Nut bonding fastener heavy duty

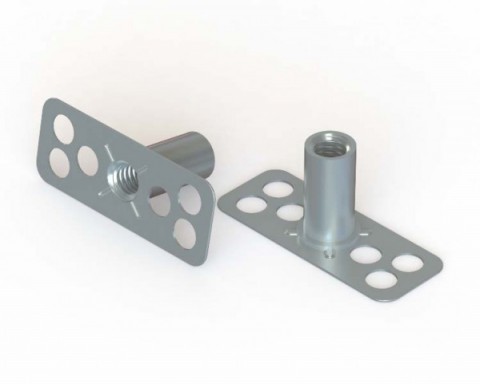

Heavy Duty Bonding Nut – Master-Plate® DFCY / DFPY

Introduction

The heavy-duty Master-Plate® DFCY/DFPY bonding nut from Specialinsert® offers strong blind fastening (M4–M6) on any adhesive-compatible material — with no drilling required. The non-perforated base plate in zinc-plated steel or stainless steel 316 ensures consistent adhesive thickness thanks to 0.5 mm spacers underneath, reducing adhesive consumption by 72% and improving bond reliability.

Description

Variations

• Thread sizes: M4–M6

• Materials: Zinc-plated steel / Stainless steel 316

• Base plate diameters: 19–58 mm

• Variants:

– DFPY open non-perforated base

– DFCY closed non-perforated base

• Excellent shear and torque resistance, thanks to the flanged nut.

Benefits of adhesive fastening

• No drilling → substrate integrity preserved

• No galvanic corrosion with stainless steel

• Ideal for thin or sensitive materials

• Uniform load transfer

• Maximum design flexibility

Adhesive guidance

We support you with professional adhesive advice through our bonding specialists.

Frequently asked questions about Nut bonding fastener heavy duty

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.