Bonding fastener

Juno Industries is the right partner to find the most performing bonding fastener for your application thanks to our 23 years of experience.

Composite materials have gained immense popularity due to their lightweight and high-strength properties, making them ideal for various applications in aerospace, automotive, marine, and construction industries. However, achieving a metal inner thread in composite materials can be a challenging task. In this guide, brought to you by Juno Industries, we will explore the process of obtaining a metal inner thread in composites. We'll also answer common questions related to tapping threads into carbon fiber, installing threaded inserts in plastic, and the use of bonding fasteners for composite applications.

Can you tap a thread into carbon fiber?

Tapping threads directly into carbon fiber is generally not recommended due to the material's delicate nature. Carbon fiber is prone to delamination and damage when subjected to traditional tapping processes. Instead, threaded inserts are preferred for securing metal threads in carbon fiber components. Juno Industries offers a range of reliable threaded inserts, such as the bonding fasteners specifically designed for use in carbon fiber materials.

How do you install a threaded insert in reinforced plastic?

Installing threaded inserts in plastic is a common practice to create strong and durable connections. The process involves heating the insert to soften the plastic, then pressing it into the pre-drilled hole until it sets in place. The plastic material reforms around the insert's threads, providing a secure hold. Juno Industries offers a variety of threaded inserts suitable for plastic applications, including the bonding fasteners that ensures optimal performance and reliability in reinforced plastics.

What is a bonding fastener?

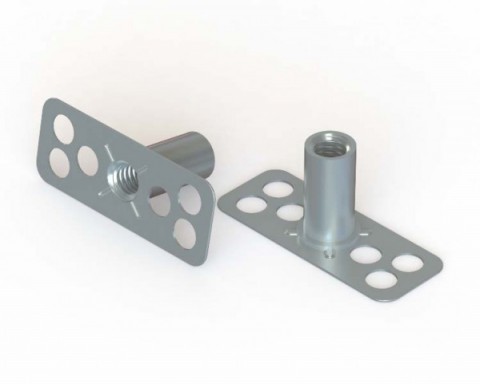

Bonding fasteners are innovative components used to attach metal hardware or other materials to composite structures. These steel zinc plated or stainless steel 316 fasteners utilize adhesive bonding to create a robust connection without the need for drilling or mechanical fasteners. Juno Industries provides a wide selection of bonding fasteners designed to simplify the assembly process and improve structural integrity in composite applications.

How does adhesive bonding work?

Adhesive bonding is a bonding technique where two materials are joined together using high-strength adhesives. The process involves preparing the bonding surfaces, applying the adhesive, and curing the assembly to achieve full strength. Adhesive bonding offers several advantages for composite applications, including even stress distribution, weight reduction, and improved fatigue resistance. Juno Industries' Master-Plate adhesive bonding fasteners offer exceptional bonding performance and reliability for composite structures.

What type of fasteners are used in composites?

When working with composites, using traditional metal fasteners may cause damage and weaken the material. Instead, specialized fasteners, such as threaded bonding fasteners, are employed to ensure a secure connection without compromising the composite's integrity. Juno Industries offers an extensive range of fasteners:

Cable bonding fastener for ty-rap fastening of cables and tubes

Male stud bonding fastener heavy duty for high performance bonding of studs

Nut bonding fastener heavy duty for high performance bonding of nuts

Insulation pin bonding fastener for fastening insulation panels without drilling

Male stud bonding fastener for bonding smaller studs

Female bonding fastener for bonding spacers

Nut bonding fasteners for bonding smaller nuts

Tailormade bonding fasteners for solving your bonding special application

Mixing dispenser guns for 2 component adhesives for several cartridge volumes

What is a bonding fastener?

A bonding fastener is a type of fastening component that employs adhesive bonding to create a strong and durable connection between two materials, typically a metal hardware and a composite structure. These fasteners eliminate the need for drilling or mechanical fasteners, reducing the risk of delamination and damage in composite materials. Juno Industries' bonding fasteners offer a reliable solution for securely attaching metal hardware to composite structures. The standard solution consits of a perforated base plate on wich the nut, stud or threaded spacer is welded and recently, our european partner Specialinsert has launched an adhesive saving solution with non-perforated base-plates that are equiped with bosses that ensure exactly the rigth amount of adhesive between the receiving material and the insert.

Conclusion about bonding fasteners from Juno Industries

Obtaining a metal inner thread in composite materials requires careful consideration and the use of appropriate fastening techniques. While tapping threads directly into carbon fiber is discouraged, threaded inserts provide a reliable solution for achieving metal threads in composites. When working with plastic composites, installing threaded inserts offers a secure and robust connection. Additionally, bonding fasteners are an innovative alternative, ensuring strong connections without compromising the integrity of the composite material.

Juno Industries is a trusted provider of high-quality threaded inserts, bonding fasteners, and adhesive solutions for composite applications. Our wide range of products, including the bonding fasteners with perforated and non-perforated base-plates, is designed to meet the unique challenges of working with composites while maintaining structural integrity and performance.

When it comes to creating a metal inner thread in composite materials, Juno Industries is your reliable partner, offering cutting-edge solutions for your specific application needs. With Juno Industries' expertise and high-performance products, you can confidently achieve strong and durable connections in your composite projects.

Ask for a sample!

As a distributor, fast delivery is almost always possible, free samples we deliver on short notice either from our warehouse or ask our manufacturer to send them directly. Delivery within 24 hours is possible on request. Feel free to ask for information and we will try to assist you as best we can, also for free samples because often tool-free assembly is possible.

Request your sample and you can test soon!

The minimum quantity is 100 pieces and 50 pieces from internal thread M10.

Available in stainless steel A4 and steel zinc plated.

Paper cataloge on request.